No main menu side bar? Then click here to access the full site in a new window

Tatra T613

...a summary by Gareth Jones

The T613 design programme was launched in 1968 to replace the distinctive, but by then outdated T603. This was to be a radical car in Tatra's terms because it would be the first non-streamlined shape since before WW2. The shape was to be more in tune with the times, and Tatra looked to the Vignale design studio in Italy. Sharp lines were becoming fashionable, with potential advantages in getting more interior space for given outside dimensions. Despite the desire for fresh thinking, the car would retain some established Tatra styling cues - the T613 was to keep the distinctive six window configuration, and the engine would be air-cooled to take advantage of all Tatra's experience. To get the required power from a compact layout, the engine would remain a V8, and for ease of access for its influential clientele there would be four big doors, with the rears having a vertical rear edge.

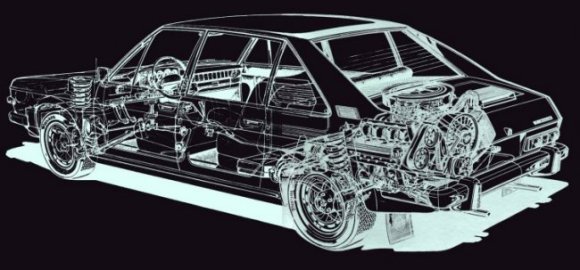

The layout of the entire car was reviewed, and for ease of maintenance it was decided to keep the engine in unit with the driven wheels. A rear engine location would always be a compromise for handling, a front engine with front wheel drive would be undesirable in a car of the planned performance, and a mid-engine layout would be too space consuming. In the event, an unusual layout was settled on. The engine was placed between the rear wheels, with the first four cylinders ahead of the axle and the rear four behind. This has been referred to as a 'semi-mid engine' and was unique in a production car. The differential was located beside the sump, with one driveshaft running through it, and the four-speed gearbox was positioned forward of the axle under the rear seat. The steering rack was mounted under the dash, with a vertical shaft to the steering arms, rather than the T603's idler link, and a short steering column for better driver safety.

The brake servo was placed under the front boot with one of the independent petrol heaters, the other petrol heater being in the cabin centre console.

The T613 was to have two petrol tanks under the rear seats, on either side of the gearbox and linked together so that there was only one filler point. The bodyshell was an all-steel monocoque with separate front seats, rather than the T603-style bench. Three styling prototypes were built, a pair of four door saloons and a two door coupe. Unfortunately the coupe was not destined for production, but Tatra would roll out plenty of other special T613 variants in due course.

The T613 entered series production in 1973 and, by the time the design was finalised, boasted an impressive specification. The air-cooled engine had a capacity of 3.5 litres, four overhead camshafts, two double barrel carburettors and capacitive-discharge ignition, like the later T603s. It developed 165 bhp at 5200 rpm and pushed the 1.6 tonne car to 60 mph in 12.5 seconds and on to a maximum of 116mph. There was a four speed manual gearbox with automatic listed as an option (but never actually offered on the regular saloon) and the gear lever was centrally placed on the tunnel. Brakes were large ventilated discs all round, with twin circuits and a servo. The suspension arrangement followed the best practice of the time with struts at the front and semi-trailing arms at the rear, to give much better control of rear wheel camber than the T603's swing axles.

As before, Tatra continued development of the T613 model, primarily to improve the interior and in 1980 the T613-2 was launched. It looked almost identical from the outside and continued through to 1986.

The T613-3 was mechanically identical, but Tatra tried to make the exterior more modern by getting rid of the chrome bumpers and some of the chrome side trim, using plastic bumpers instead, and a new panel between the headlights. The outer headlights were changed for larger ones and the front indicators were now built into the wings.

The hub caps changed from chrome to various plastic styles, and the interior was modernised in materials and design. Another throwback to the previous decade (or even the decade before that), the quarterlights in the front door windows, with their clever knurled knobs, were deleted. As ever, a low volume manufacturer like Tatra sought to limit the need to tool up for dedicated parts, so several interior fittings and switches were either PAL or Škoda parts. This does not detract from the driving experience, so there is no need to tell anyone that the rear air extract vents were from an FSO.

By 1990 the technology of 1974 was somewhat dated. What was needed was a body and engine overhaul, and help came from the UK. Former Jaguar development engineer Tim Bishop had approached the world's car makers with his expertise in meeting modern exhaust emission standards and Tatra responded. Bishop was struck by the unusual car's potential to provide a niche model to a wider western market, and won a contract to redevelop the whole car. His small team, trading as Tatra Motive Power and including Mark Berry and ex-Saab stylist Geoff Wardle, came up with the T613-5 prototypes, but engine modifications came first and were incorporated into the existing T613-4. To meet new emission standards meant fitting catalytic converters, and a sophisticated engine management system was designed, giving precise control of fuel and ignition to maintain the power and clean up the exhaust. Using experience of other systems, the fuel injection was basically the best of everything seen before, and featured multi-point sequential injection, a two-stage throttle and 'learning' parameters to adapt to your driving style. With modified camshafts for better breathing this gave 200bhp at 5750rpm but there was more to come. For added power there was a sensor on the accelerator which shut off the fan at full throttle and maximum revs. This only works for a short time but the end result is 220bhp, more than the contemporary Jaguar 3.4, the Mercedes 3.5 or the BMW 3.5 engines.

This T613-4 engine above shows the additional plumbing of the later injected engines. The large (Iveco truck) air cleaner ducts air into the aluminium throttle body with its feedback loops and idle sensor. On the right hand inner wing are some of the fuses and relays, and in a compartment behind them lives the control unit. The large aluminium radiator towards the rear is the air conditioning condensor, with its compressor just forward of it. After all this revision, what difference does the driver see? As well as smooth power delivery and better low speed torque (if you are feeling lazy you can change up a gear at 1200 rpm) the performance figures spoke for themselves - 9 seconds to 60 mph and a top speed of 143 mph. A new five-speed gearbox was developed but the gear ratios are quite high for cruising, rather than sprinting. However do not underestimate the benefits of being able to get to 70 mph in second gear!

The outside of the car was relatively unchanged, but for an integrated chin spoiler. This car has the alloy wheels that were an option, and has lowered suspension to improve looks and handling.

The interior was improved, too. Leather seats were an option as were electric windows, air conditioning, power steering, central locking, an electric dipping rear view mirror and even an electronic dashboard with 'talking' computer.

By 1993 the T613-5 was ready. Four rhd prototype cars were made for the UK market and this is where the whole car got the overhaul it needed to keep up with its western counterparts. The fuel injected engine remained the same but the gearbox had lower ratios (although the high ratios were an option) and a revised gearshift pattern. The new car could now sprint to 60 mph in around 7.5 seconds and reach 134 mph. Under the skin, there were numerous sheet metal changes to help the handling and redistribute the weight, but this was not a simple operation. For example, the air-con condensor was moved from the engine bay to the front but this meant fitting two separate electric fans to cool it, and also changing the spare wheel access.

Visible external changes were harder to find, the front panel between the headlights was different, and bumpers were changed to incorporate spotlights in the front air dam, and an air intake for the condenser. Inside, things were very different, and the team tried to raise the standard of cabin trim to suit western executive tastes, resulting in an ambience more like a contemporary Bristol's than the Jaguar that was its inspiration. The dashboard was now wood instead of plastic and had a completely revised layout with a new digital control panel for the programmable petrol heater (now one heater not two).

After the prototypes were built, Tatra chose a somewhat different specification for subsequent T613-4s with the fascia remaining in the style of previous production cars, but usually covered in leather. The door skins and handles were slightly different, and would be carried over to the T700 along with bonded-in screens. These cars continued up to 1996 when the T613 was replaced by the T700.

T613 variants

There were numerous special 613s made during the life of the car and as is common with Tatra information there is a lack of hard evidence to describe accurate specification, so if there are innacuracies here, please let us know.

The T613 was of course meant for senior Czech figures, but an even more exclusive model was available. This is the S model, or Speciál and is pictured below.

The wheelbase is 6" longer, and the Speciál also has rectangular headlights with a different front panel, a different interior, dual ignition for reliability, and power steering. The power steering is different from the Series 4 and 5 cars and the Speciál was built in very low quantities. This is not to be confused with the long wheelbase version of the standard T613 because of the headlights, interior and dual ignition.

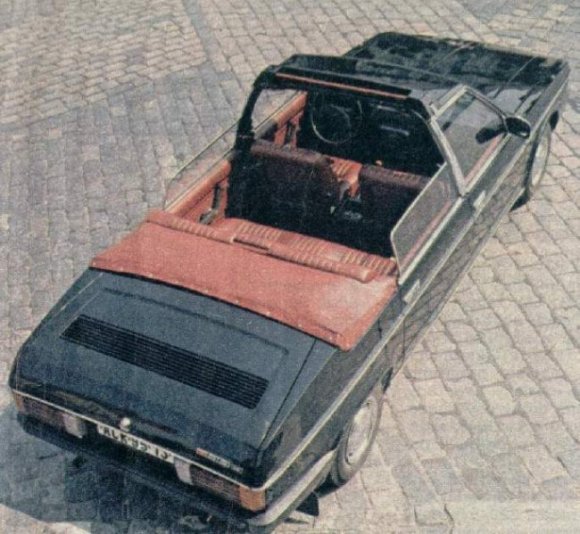

An even grander version, the T613K or Cabriolet was made, similar to the Speciál but it is thought that at least some Ks were fitted with automatic transmission to make it easier when transporting dignitaries at parade speeds.

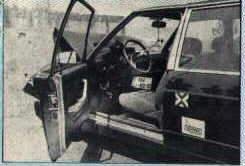

A different type of passenger was catered for in another T613 special body. A stretcher could be laid out in the back of the T613RTZ Ambulance. This was built on an even longer wheelbase platform and was made alongside the saloons for most of the model's life. The large side door gave easy access for the ambulance crew and the stretcher was loaded in through the rear door and over the top of the sealed engine bay.

To keep up with the power requirements of the lights, sirens and other equipment, there was a single, very large 12v battery in the front, rather than the two 6v batteries normally carried in each front inner wing. The ambulances also had power steering but the later cars never changed to the fuel injected engines. Special allowances were made for emissions on Czech emergency service vehicles, and the Tatra was exempt. The reason for not changing that the later engine is taller than the carburettor equipped model, so lots of changes would be required for tooling of the rear door and stretcher area. The ambulances were popular at race tracks and, even with the old technology, they could still manage over 100 mph. The rear bodywork is a mixture of glass-fibre and steel and the remainder of the body followed whatever was current in the mainstream T613 cars. Production continued up to 1995, with the last few examples being used by Tatra as support vehicles for their racing trucks. What else could carry so many spare parts at that sort of speed?

The T613 saloon was used as the basis for other service vehicles. The police used both unmarked and fully liveried cars, and they often had more power than the standard cars, with a higher compression ratio and different camshafts. Another application was for testing the grip on runway surfaces, with the T613RT (Runway Tester). The car was a T613 saloon, but the rear seats were removed and a large hole was cut in the rear floor area. An aircraft wheel and part of the undercarriage was fitted to allow the aircraft wheel to be lowered onto the runway, which allowed the test team to check that the runway surface provided sufficient friction to prevent the aircraft wheel from skidding.

Finally there was the T623, a different model number but clearly a T613 in not-very-good disguise. This was built as a pace car for racing circuits, and the design brief was to make sure that this large, heavy saloon would not hold up the racing cars in too embarrassing a way. To achieve this, the T623s had stripped out interiors and 3.7 litre engines, producing 174bhp.

As with the ambulance and RT, the T623 body detail changed in line with the mainstream T613, as the pictures above show.

No main menu side bar? Then click here to access the full site